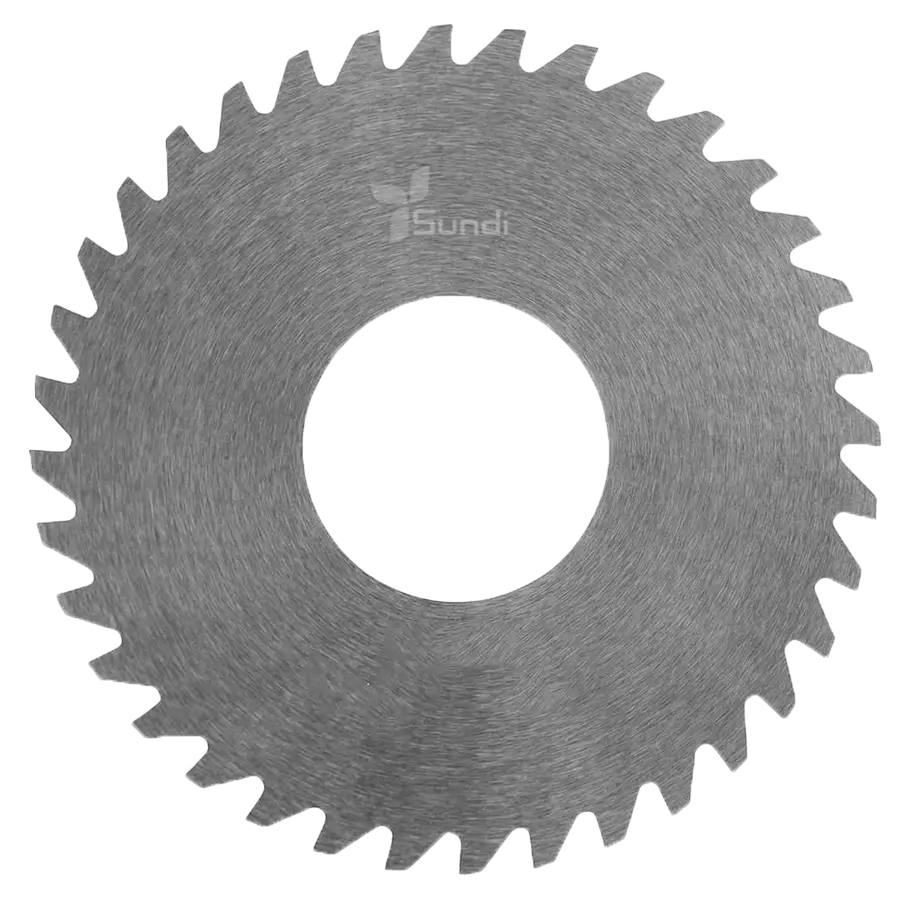

Solid carbide circular saw blades

SUNDI offers high-performance solid carbide circular saw blades manufactured to DIN standards. If you require non-standard dimensions, we also provide custom tooling solutions tailored to your specific cutting needs.

Our range of solide circular saw blades

Our Solid Carbide Circular Saw Blades are available in two DIN standards—DIN 1837 and DIN 1838—with two different tooth profiles. They come in diameters ranging from Ø20 to Ø250 mm and thicknesses from 0.2 to 6 mm. Custom dimensions are also available to meet specific customer requirements.

These carbide circular saw blades feature excellent surface finish with mirror-polished surfaces that ensure clean cuts while maintaining precise dimensional tolerances. Combining high hardness with outstanding toughness, our blades are ideal for applications that demand both precision and durability.

Applications include cutting:

Steel and stainless steel

Non-ferrous metals (e.g., copper, aluminum, brass)

Hard plastics (e.g., PVC, PEEK, PTFE)

Carbon fiber and glass fiber reinforced composites (CFRP, GFRP)

- Обеспечение качества

- Обслуживание OEM/ODM

- Экономия средств

- Быстрая доставка

Specifications of solide circular saw blades

DIN 1837 A

- Fine-toothed

For cutting thin sheets or making shallow grooves.

DIN 1838 B

- Coarse toothed

For cutting thick materials or making deep grooves.

DIN 1837

| Толщина | Blade Diam. (mm) | 15 | 20 | 25 | 30 | 40 | 50 | 63 | 80 | 100 | 125 | 150 | 160 | 200 |

| Blade Bore (mm) | 5 | 5 | 8 | 8 | 10 | 13 | 16 | 22 | 22 | 22 | 32 | 32 | 32 | |

| 0.2 | Blade Teeth | 64 | 80 | 80 | 100 | 128 | 128 | |||||||

| 0.25 | 64 | 64 | 80 | 100 | 128 | 128 | 160 | |||||||

| 0.3 | 64 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | ||||||

| 0.4 | 64 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | ||||||

| 0.5 | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | |||||

| 0.6 | 48 | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | |||||

| 0.8 | 40 | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | ||||

| 1 | 40 | 40 | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 150 | 160 | 160 | |

| 1.2 | 40 | 40 | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 150 | 160 | ||

| 1.6 | 40 | 40 | 40 | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 150 | 160 | 160 | |

| 2 | 40 | 32 | 40 | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 128 | 160 | |

| 2.5 | 40 | 32 | 40 | 40 | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 128 | 160 | |

| 3 | 40 | 32 | 32 | 40 | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 128 | |

| 4 | 24 | 24 | 32 | 40 | 40 | 48 | 64 | 64 | 80 | 100 | 128 | 128 | 128 | |

| 5 | 24 | 24 | 32 | 32 | 40 | 48 | 48 | 64 | 80 | 80 | ||||

| 6 | 24 | 24 | 24 | 32 | 40 | 40 | 48 | 64 | 64 | 80 |

DIN 1838

| Толщина | Blade Diam. (mm) | 15 | 20 | 25 | 30 | 40 | 50 | 63 | 80 | 100 | 125 | 150 | 160 | 200 |

| Blade Bore (mm) | 5 | 5 | 8 | 8 | 10 | 13 | 16 | 22 | 22 | 22 | 32 | 32 | 32 | |

| 0.2 | Blade Teeth | 20 | 20 | 20 | 30 | 40 | ||||||||

| 0.25 | 20 | 20 | 20 | 30 | 40 | |||||||||

| 0.3 | 20 | 20 | 20 | 30 | 40 | |||||||||

| 0.4 | 20 | 20 | 20 | 30 | 40 | 48 | 64 | |||||||

| 0.5 | 20 | 20 | 20 | 30 | 40 | 48 | 64 | 64 | 80 | |||||

| 0.6 | 20 | 20 | 20 | 30 | 40 | 48 | 64 | 64 | 80 | 80 | ||||

| 0.8 | 20 | 20 | 20 | 24 | 32 | 40 | 48 | 64 | 64 | 80 | ||||

| 1 | 20 | 20 | 20 | 24 | 32 | 40 | 48 | 48 | 64 | 80 | 80 | 80 | ||

| 1.2 | 20 | 20 | 20 | 24 | 32 | 40 | 40 | 48 | 64 | 64 | 80 | 80 | ||

| 1.6 | 20 | 20 | 20 | 24 | 32 | 32 | 40 | 48 | 48 | 64 | 80 | 80 | 80 | |

| 2 | 20 | 20 | 20 | 24 | 24 | 32 | 40 | 40 | 48 | 64 | 64 | 64 | 80 | |

| 2.5 | 20 | 20 | 20 | 24 | 24 | 32 | 32 | 40 | 48 | 48 | 64 | 64 | 80 | |

| 3 | 20 | 20 | 20 | 24 | 24 | 24 | 32 | 40 | 40 | 48 | 64 | 64 | 64 | |

| 4 | 20 | 20 | 20 | 24 | 20 | 24 | 32 | 32 | 40 | 48 | 64 | 64 | 64 | |

| 5 | 20 | 20 | 20 | 24 | 20 | 24 | 24 | 32 | 40 | 40 | ||||

| 6 | 20 | 20 | 20 | 24 | 20 | 20 | 24 | 32 | 32 | 40 |