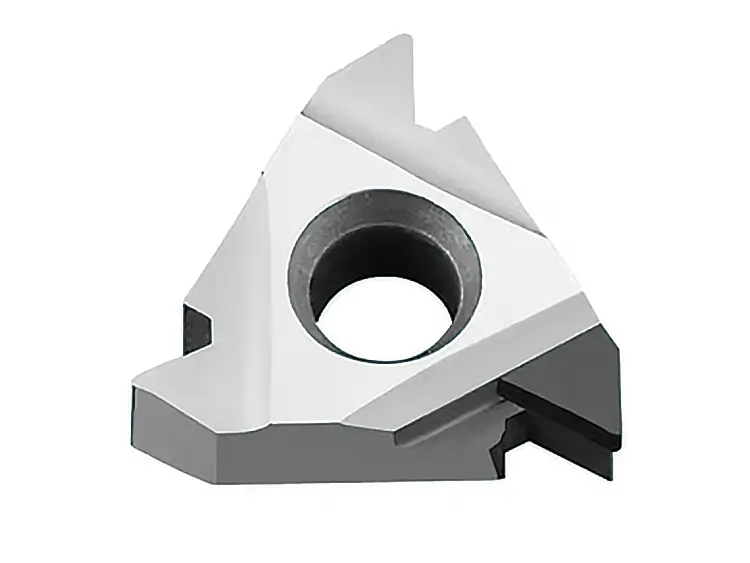

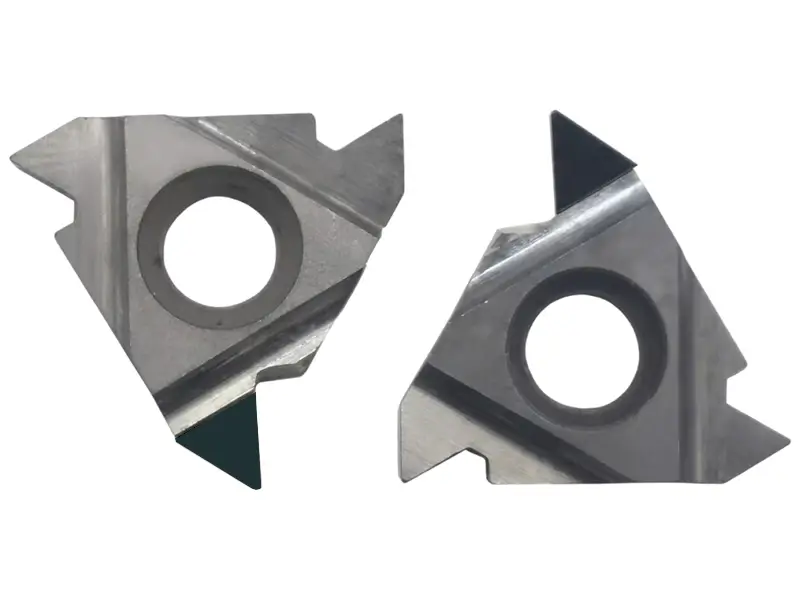

Insertos PCD para roscado

When machining threads in abrasive non-ferrous materials like high-silicon aluminum, copper, brass, or carbon fiber, standard carbide tools often fail to deliver consistent quality. Sundi PCD (Polycrystalline Diamond) Threading Inserts are engineered to solve this challenge, offering unmatched wear resistance and dimensional stability.

Designed for high-volume CNC production, our PCD Threading Inserts ensure your threads meet the strictest tolerance requirements while significantly lowering your cost per part.

Versatile Threading Solutions by Sundi

We offer a comprehensive range of PCD Threading Inserts tailored to various machining needs, covering all major international thread standards.

External Threading: Rigid insert designs for high-precision external threading on shafts and fittings.

Internal Threading: Optimized geometries for deep bore threading requiring excellent chip control.

Standard Profiles: Full profile inserts available for ISO Metric (M), Unified (UN/UNF), NPT, and Whitworth (BSW) standards.

Custom Threading: Custom Sundi PCD profiles for specific thread forms, Acme threads, or Trapezoidal threads.

Ideal Materials for Sundi PCD Threading Tools

Please note: PCD Threading Inserts are strictly designed for non-ferrous materials. Using them on ferrous metals (Iron/Steel) will cause rapid chemical wear and failure.

Aluminum Alloys: Perfect for threading automotive ports, aerospace fasteners, and fluid fittings.

Copper & Brass: Ideal for threading plumbing components, electronic connectors, and valves.

Carbon Fiber (CFRP): Clean thread cutting without delamination or fiber pull-out.

Engineering Plastics: Smooth thread flanks for PEEK, Acrylic, and Nylon threading.

- Precious Metals: Gold, Silver, and Platinum (for jewelry manufacturing).

- Gran resistencia al desgaste

- Reducir el tiempo de máquina

- Rendimiento estable

- Fácil de usar

Advantages of Sundi PCD Inserts in Thread Turning

When it comes to roscado non-ferrous materials, standard tools often fail due to built-up edge (BUE) causing poor surface finish and dimensional loss. Sundi PCD Threading Inserts solve these challenges.

-

Unmatched Wear Resistance in Abrasive Threading

High-silicon aluminum (Si > 12%) is notoriously abrasive on thread profiles. Sundi PCD threading grades maintain the correct thread form and sharp cutting edge significantly longer, ensuring that your threading tolerance remains stable over thousands of parts.

-

2. Burr-Free & Mirror-Finish Thread Quality

Achieve a surface roughness of Ra 0.4 or better on thread flanks. The ultra-low friction coefficient of our diamond tips prevents chips from welding to the tool during the threading process. This eliminates galling and ensures clean, burr-free threads from the first pass to the last.

-

3. High-Speed Threading Capability

Boost your productivity. Sundi PCD allows for significantly higher cutting speeds (Vc) in threading cycles compared to carbide, reducing cycle time and increasing your daily throughput.

Technical Specifications for PCD Threading

Sundi PCD Threading Inserts are compatible with standard ISO threading holders and specialized systems.

| Característica | Specification | Benefit for Threading |

| Material | Premium Grade PCD (Polycrystalline Diamond) | Extreme hardness for abrasive roscado. |

| Thread Pitch | 0.5mm – 6.0mm (48 – 4 TPI) | Flexibility for fine to coarse roscado tasks. |

| Profile Type | Full Profile / Partial Profile 60° & 55° | Optimized for productivity or versatility. |

| Refrigerante | High-Pressure Coolant Compatible | Critical for chip evacuation in internal roscado. |

| Aplicación | Non-Ferrous Metals & Non-Metals | Dedicated to Aluminum, Copper, Plastic. |

Ready to Optimize Your Threading Process?

Stop settling for torn threads and frequent tool adjustments. Switch to Sundi PCD Threading Inserts today and experience the difference in precision and longevity.

PREGUNTAS FRECUENTES

Preguntas y respuestas más frecuentes

A: No. For stainless steel and titanium, we recommend our specialized Carbide or CBN grades. PCD is designed specifically for non-ferrous materials.

A: Yes. You can typically increase your surface speed (RPM) significantly compared to carbide, which improves productivity.

A: Yes, we excel at custom profile grinding. Beyond standard ISO or UN threads, we can produce inserts for complex shapes like Acme, Buttress, API, or any custom geometry you require. Simply provide your part drawing, and we will design the tool to match your exact thread specifications.