Insertos PCD para mandrinado

Are you facing challenges with chatter, tapered holes, or poor surface finishes during internal turning (boring) operations?

Sundi PCD Boring Inserts are designed to solve the unique difficulties of machining inside a bore. With ultra-sharp cutting edges and low-friction diamond surfaces, Sundi tools minimize cutting pressure—critical for preventing tool deflection in deep holes. Experience tool life 20x to 50x longer than carbide while maintaining tight ISO hole tolerances.

Versatile Boring Solutions

We offer a comprehensive range of Insertos PCD para mandrinado tailored to various internal turning needs, ensuring compatibility with your existing boring bars.

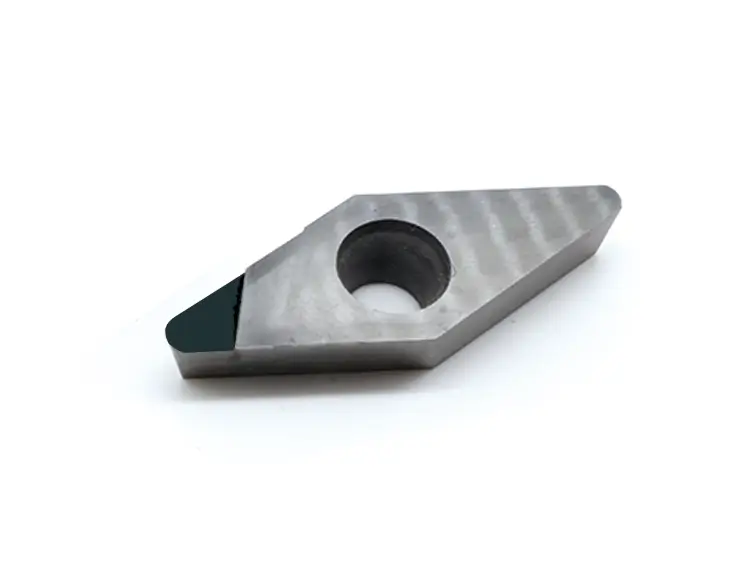

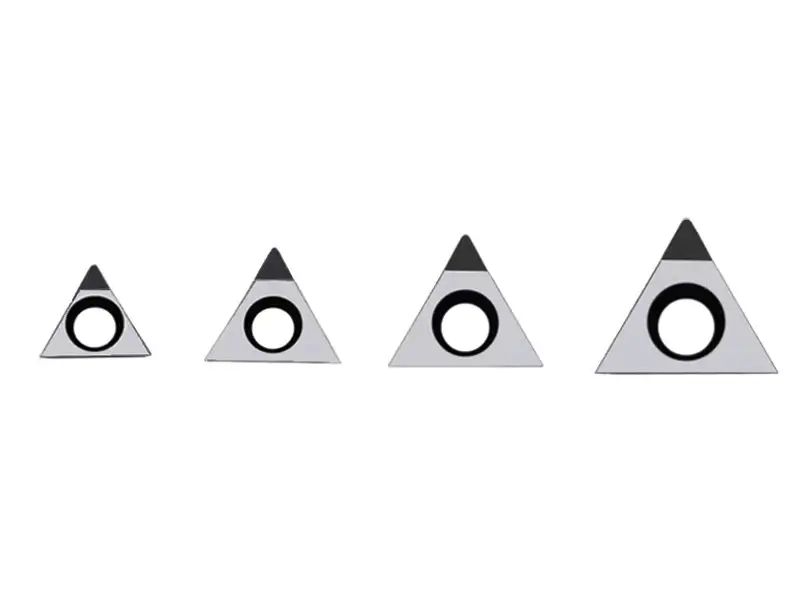

General Purpose Boring (Rhombic 80° & 55°): The most versatile insert shapes for standard internal turning and facing operations, offering a perfect balance of strength and accessibility.

Profiling & Undercutting (Diamond 35°): Acute angle inserts designed for complex internal contours, deep undercuts, and spherical boring where tool clearance is critical.

Heavy-Duty Roughing (Square): Robust insert geometry designed for maximizing stability and material removal rates in larger bore diameters.

Precision Fine Boring: Specialized inserts optimized for high-precision adjustable boring heads, essential for cylinder finishing and achieving tight H6 tolerances.

Target Applications for Internal Turning

Sundi PCD Boring Inserts are essential for industries requiring high-precision internal geometries. Strictly for non-ferrous materials.

Automotive Cylinders: Precision boring of master cylinders, brake calipers, and piston liners.

Electric Motor Housings: Machining the internal stator bore in aluminum casings.

Bearing Housings: Achieving tight interference fits for bearing insertion.

Aerospace Bushings: High-tolerance boring of bronze or composite bushings.

- Gran resistencia al desgaste

- Reducir el tiempo de máquina

- Rendimiento estable

- Fácil de usar

Why Choose Sundi PCD for Boring Operations?

Boring is distinct from external turning because the tool is often long and slender, making it prone to vibration. Sundi PCD Boring Inserts are optimized to counter these issues.

-

1. Low Cutting Pressure = Less Vibration

In boring, tool deflection causes chatter marks. Sundi PCD inserts feature positive rake angles and razor-sharp edges that slice through aluminum with minimal resistance. This low cutting pressure stabilizes the boring bar, ensuring a perfectly round and straight hole without "bell-mouthing."

-

2. Consistent Hole Tolerances (H6/H7)

Maintaining a precise bore diameter over a long production run is difficult with carbide due to rapid wear. Sundi’s extreme diamond hardness ensures the cutting edge doesn't retreat. You can bore thousands of parts without constantly adjusting your CNC machine offsets to compensate for size loss.

-

3. Superior Chip Evacuation

Chips trapped inside a bore can scratch the finished surface. The exceptionally smooth top face of Sundi PCD inserts allows chips to slide off effortlessly and evacuate quickly, protecting the surface finish (Ra 0.2 - 0.4) of your internal walls.

Technical Specifications

Sundi PCD Boring Inserts are ground to strict micro-tolerances to ensure repeatability when indexing the tool.

| Característica | Specification | Boring Benefit |

| Geometry Standards | ISO Standard Positive Inserts | Compatible with all standard boring bars. |

| Nose Radius (R) | 0.1mm – 0.8mm | 0.2mm or 0.4mm recommended for best finish. |

| Rake Angle | High Positive (Sharp) | Reduces cutting force and vibration (Chatter). |

| Cutting Edge | Tipped PCD (1 Corner) | Cost-effective solution for internal finishing. |

| Suitability | Non-Ferrous Materials | Aluminum, Brass, Bronze, PTFE. |

Stop Scrapping Parts due to Oversized Holes

Ensure every bore is perfectly round and to spec. Switch to Sundi PCD Boring Inserts for unmatched precision and consistency in your internal turning operations.

PREGUNTAS FRECUENTES

Preguntas y respuestas más frecuentes

A: Chatter is often caused by high cutting forces pushing the boring bar away. Sundi PCD inserts are much sharper than coated carbide, which significantly lowers this cutting pressure. This “free-cutting” action allows the tool to cut cleanly without inducing the vibration that causes chatter.

A: Yes, but they excel at Acabado. While Sundi PCD can handle roughing cuts, its primary value in boring is holding the final size and surface finish. Many shops use carbide for the rough bore and switch to Sundi PCD for the final pass to guarantee the tolerance.

A: With a rigid setup and proper parameters, Sundi PCD Boring Inserts can easily achieve a mirror finish of Ra 0.2 to 0.4 µm. This often eliminates the need for secondary roller burnishing or honing operations.