CNC profile router bits for wood

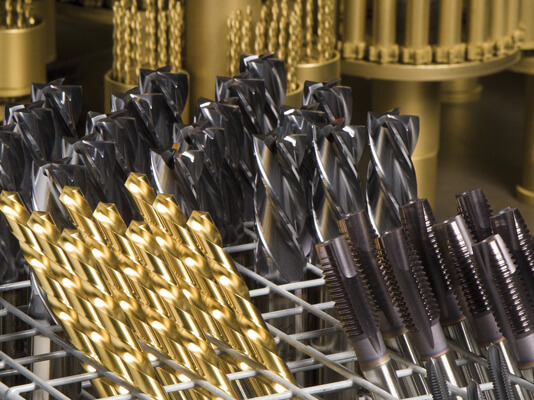

cnc router bits for wood are widely used For CNC Engraving, Milling, Roughing, Hollowing, and 3D sculpturing purposes

CNC router bits for wood product design and solutions

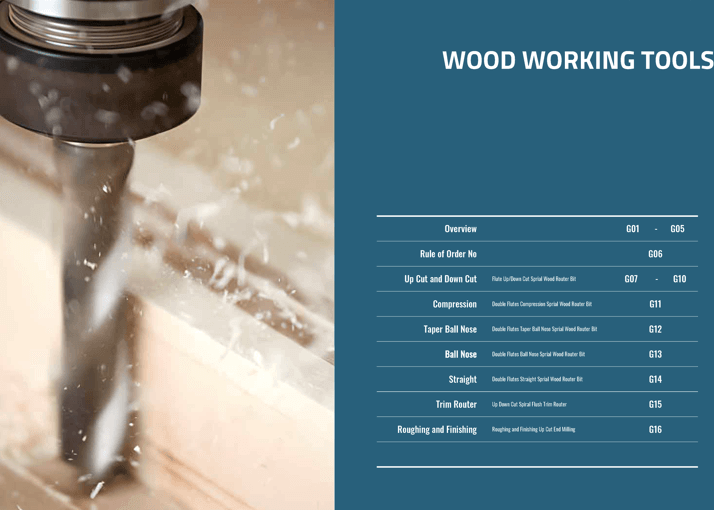

There are numerous types of profile router bits, each serving a different function. Different router tools types have different applications. They control the type of processing you can perform, the clarity of your finished designs, and the speed at which you can work with the material.

Our Mission

We aim to offer total customer satisfaction with the endless pursuit of Excellence in Solutions, Quality, and Service.

Our Capacity

We supply a wide range of profile router bits products, each serving a different function. Different router bit types have different applications. They control the type of processing you can perform, the clarity of your finished designs, and the speed at which you can work with the material.

We Are One Of The Best Maker Of CNC router bits for wood

SUNDI designs and manufactures profile router bits for customers worldwide in a variety of industries. Our router drill bits are used for rough or precision machining of ABS, PVC, acrylic, nylon, resin, density board, melamine chipboard, softwood/hardwood, particleboard, composite board, solid wood, native wood, plywood/veneer plywood, laminate, laminated plywood, and other materials to achieve the desired finish and accuracy of parts.

Whether you are carving/cutting/engraving/milling/slotting/sculpting, tooling can be optimized for the entire product life cycle through our proven process. Not only do we specialize in developing cutting tool solutions to improve the quality of their product optimized we also help our customers increase their production

- Clean Cut & Excellent Edge-Grinding

- Smooth cutting and fast chip-removal

- Industrial quality control to ensure best performance

- High Efficiency, Durable, High Precision

- Not Easy To Break.

- It Is Smokeless And Burr-Free While Processing.

find the CNC router bits for wood set with different form

find the CNC router bits for wood with different application

Material Application of profile router bits

Connect with the Sundi Tools Sales Team

Common the CNC router bits for wood Coating Performance

The coating is a micro-thin DLC coating that enables the tool’s cutting edge to retain crucial sharpness and lubricity. This provides longevity and produces cutting results of the highest quality.

- With brilliant distinctively-tinted coloring, provides additional improvements to router tooling

- Colorful DLC + Density Carbide = 2X increased life and performance vs. standard uncoated bits

Note: Multi-colored hues, while attractive, will dissipate upon use, and yet coating will remain fully effective.

| COATING | Color | Hardness | MAX.working Temp | coated thickness |

|---|---|---|---|---|

| TIN | Bronze | 2400HV | 600°C | 1-3μm |

| TIALN | Colorfui | 2800HV | 400°C | 1-3μm |

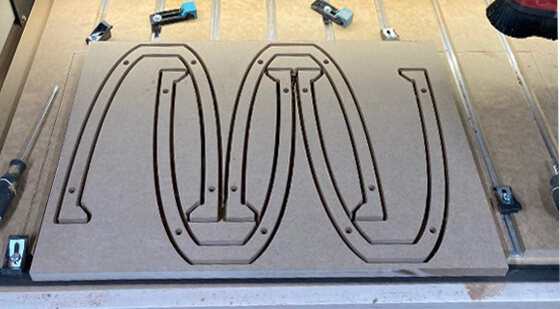

User Case of CNC router bits for wood(1/4 router bit sets 1/2 shank)

I use 1/4 router bit sets for cutting numerous MDF parts on my benchtop CNC. I leave a clean edge on the top and a decent edge on the bottom. Definitely worth the money and I will be buying more as needed.

This was my first hand wood router, I wanted to try one and decided to give it a go. I love this little bit, I use this for clearing out most of my waste material now over other 1/4″ end mills. It leaves a clean finish and has stayed sharp for a few weeks. I cut a lot of hard maple and pine.

Connect Us Now

What made us different

-

7×24 Hrs

7x24Hrs online for technical supports

-

cost reduce

The same quality compared with the top-brand, but half or quarter cost.

-

Express shipping

Worldwide shipment (UPS,DHL,FedEx,TNT)

-

Worry-Free Service

Quality assurance and after-sales without worries for as long as 12months

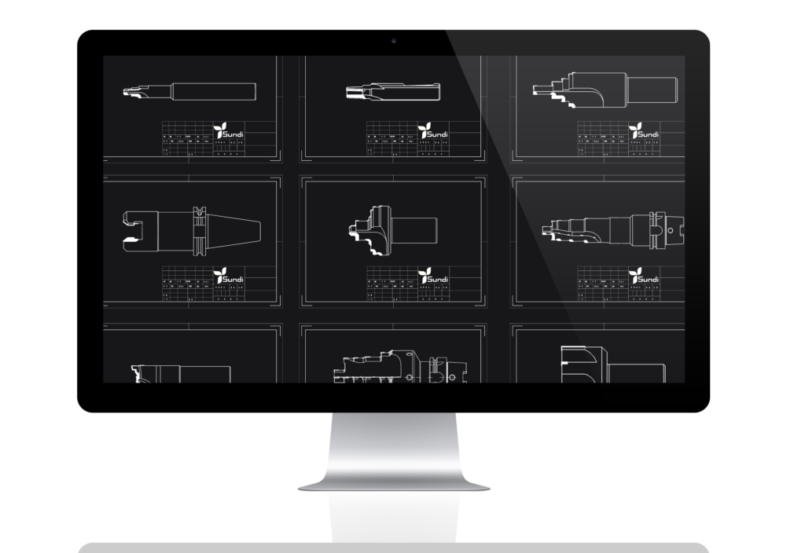

the steps show How we made the CNC router drill bits

-

Step 1: Analysis And Design

-

Step 1: Analysis And Design

With consumer plenarily communication, Deepens know consumer requirement, According to consumer requirements, including accuracy, roughness, working life. We will fabricate a qualified carbide end mill set for different applications.

-

Step 2: Suitable Material Selection

-

Step 2: Suitable Material Selection

Following the different applications, we will choose the tungsten carbide rods with different specifications and performance. The tolerance of shank diameter is 0/-0.005mm, which will restrain the vibration during high-speed cutting.

-

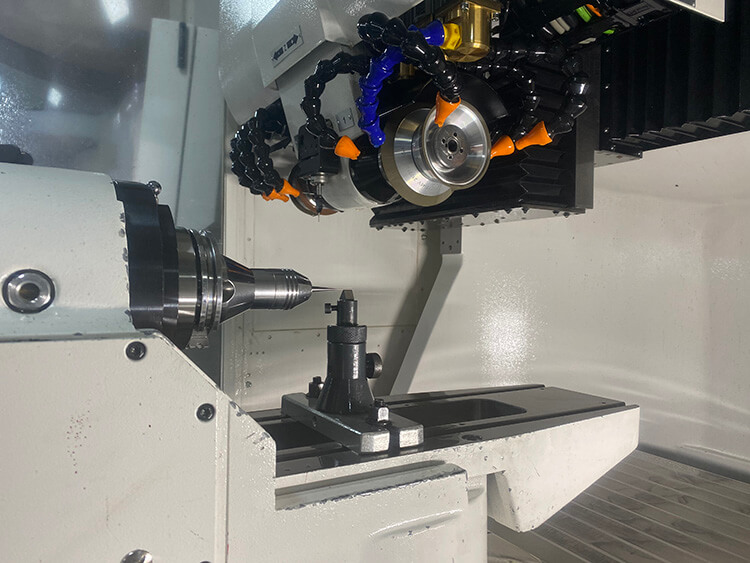

Step 3:Produced by Walter

-

Step 3:Produced by Walter

Our Walter machines can be used for both production and re-grinding, and show excellent performance in improving the high efficiency of producing the metal cutting tools. The Walter machine body has great deadweight and rigidity, it can effectively avoid the impact of vibration, thus ensuring high grinding accuracy. Combined with 24 pieces of grinding wheel in storage, our machines can meet the requirements of complex geometry structure and large-scale milling cutter production.

-

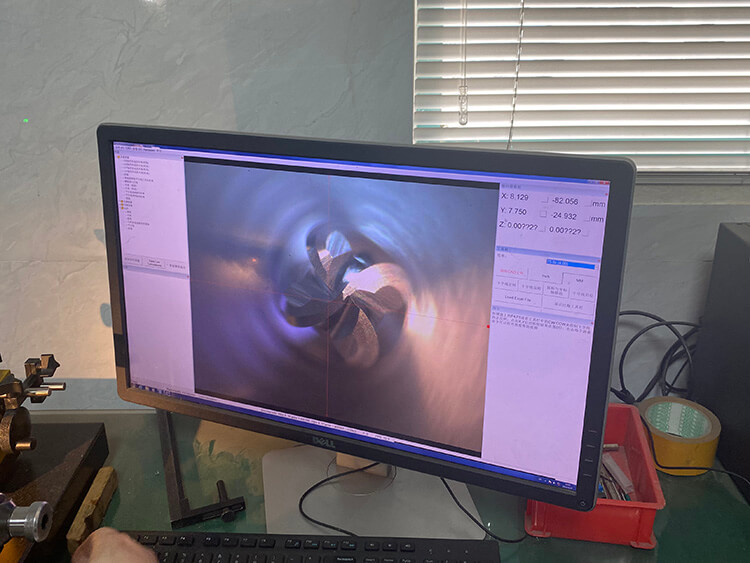

Step 4: Measure

-

Step 4: Measure

Once we have finished the carbide end mill production, we will do a complete test on the tool Zoller, including every diameter, angle, and arc. All of them need to be checked by the program before passing to our QC.

-

Step 5: Coating

-

Step 5: Coating

As a chemical and thermal barrier, the coating process can reduce the diffusion and chemical reaction between the tool and the workpiece, thereby reducing the wear of the matrix. The end mill after the coating has many advantages, such as high surface hardness, good wear resistance, stable chemical properties, heat resistance, and oxidation resistance, a small friction coefficient, and low thermal conductivity characteristics. The cutting life of the end mills is increased 3~5 times more than an uncoated, cutting speed is increased by 20%~70%, the processing accuracy is improved by 0.5~1 level, and the total cost is reduced by 20%~50%.

-

Step 6: Package and Delivery

-

Step 6: Package and Delivery

Our skilled QC will inspect the tools with dimensions and surface finish, then package and delivery.

troubles shooting

Sometimes, we are encountering the problems when using the solid inserts, the following are the typical situations that you may face

cutting blade borken

-

1

Feed rate too high

reduce the feed rate

-

2

Cuttng direction is not right

changed the direction

-

3

Blade too sharp

chamfer and roundness the cutting edge

-

4

Tools not fixed well

checking and fixed the collet

-

5

Vibration

reduce the turning speed

Tool broken

-

1

too much cutting output

reduce the cutting parameter

-

2

Cutting resistance too much

reduce the feed ,increase the turning speed

-

3

Tools too long

Adjust the suitable tools

Wear too fast

-

1

Feed rate too low

increase the feed rate

-

2

Cutting direction is incorrect

changed the cutting direction

-

3

The hardness of material is too high

choose the suitable and right tools

surface roughness bad

-

1

Vibration

adjust the cutting parameter

-

2

Chip remove bad

adjust the enulsion ,increased the cutting speed

-

3

Feed rate too high ,but low turning speed

adjust the correct cutting parameter

Documents

FAQ

Most frequent questions and answers

Sundi Tools is a brand that offers a range of high-quality woodworking tools. One of their best routers for woodworking is the Sundi Double Flutes Spiral Compression-Cut router bit .

There are several types of wood routers available on the market, each designed for specific woodworking tasks. Here are some of the most common types of wood routers:up cut /down cut/Compression cut

Wood routers come in different types, including fixed-base and plunge routers. To choose the right one, consider factors like the base type, motor power, and variable speed. We offer high-performance router bits, which you can check in our catalog on the right-hand side. If you have questions, please contact us.

The cheapest option available for wood routers is a trim router, which is a small and basic type of router used for light woodworking tasks. It is usually less powerful than other types of routers and is ideal for tasks like trimming and shaping edges. However, it may not be suitable for heavy-duty tasks. Other types of routers used in woodworking, such as fixed-base is typically more expensive than trim routers.

Some of the most reviewed products in the wood router machine category include the DEWALT DW618PK, Bosch 1617EVSPK, and Makita RT0701CX7. These routers are popular among woodworkers for their reliability, versatility, and ease of use. They come with both plunge and fixed bases, variable speed control, and powerful motors suitable for different woodworking tasks.