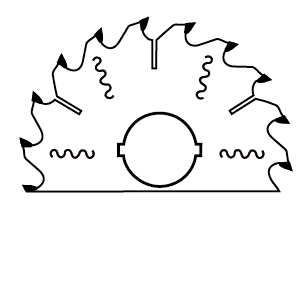

CUTTING TOOLS

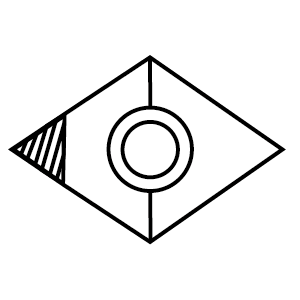

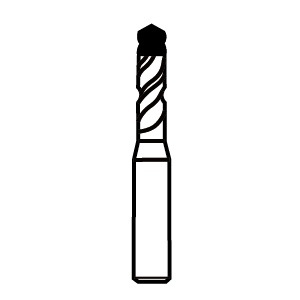

PCD CBN Cutting Tools

INTRODUCTION

Carbide Cutting Tools

Find a reliable supplier that can handle a wide range of custom and standard applications Look no further

TEAM SUPPORT

Expert Engineering Support

We provide OEM manufacturing, complete design solutions, worry-free pre-sales and after-sales service, and our experienced engineering team is always on standby.

We Work With Great Companies

Our Mission

Dear Customer, SUNDI aims to offer clients the most cost-effective service and solutions. Our tools present the most comprehensive range of PCD, PCBN, and Carbide cutting tools. Our solution, expertise, and technical support make us your perfect partner when performing tasks, facing challenges, and completing projects.

Why Trust SUNDI ? Reliable Results, Not Just Tools.

Sourcing internationally shouldn't be stressful. We combine stable quality with smooth processes to give you the performance you expect, without the risks.

But don't just take our word for it — [see what our customers say].

4 Simple Steps

Send Inquiry

Upload your drawings or RFQ. We review them and quote fast.

Confirm Design

Our engineers verify the specs. You approve the final drawing before we start.

Precision Manufacturing

We produce your tools with strict quality control (ISO standards).

Global Delivery

We handle the shipping. You receive the goods, ready to use.

Good Partner Great Future

While you negotiate a 2% discount with local big brands, your competitors are sourcing directly from China's premier cluster, securing a 300% profit margin advantage. Every day you wait is a day of lost competitive edge.

I am really very like that i ordered PCD Reamer from your trials, I think that would be very good. Precize manufacturing quality is absolutely perfect.

TOM Customer ServiceI saw the client this morning and he told me that the tools had worked very well.They very satisfied with the result!As soon as we have consultation for this type of product we will re-order

Kade Sato Manufacturing TechnicianWe satisfied with they quanlity and service ,they always quick reaction and delivery on time helps me a lot!

Melinda Lai Purchasing ManagerFind The Tools By Application

For Aerospace Industry

in aerospace manufacturing for high-precision machining and meeting process requirements. With non-standard customization options, they improve efficiency and reduce costs, making them a top choice for aerospace manufacturers. The result is sustainable production and driving progress in the industry.

Application

- 1

Carbon fiber composites, high-silicon aluminum, magnesium alloys

- 2

Milling aerospace structures, engine blades,

- 3

Aluminum alloy parts

- 4

aluminum, titanium, high-temperature alloys

Advantage

- 1

Material compatibility:

Versatile tools for diverse aerospace materials.

- 2

Improved surface finish

Minimizing burrs, enhancing part quality

- 3

Customizability

ailored solutions for optimized machining processes

For Automotive Industry

PCD cutting tools are very important for working on high-precision cast aluminum parts in the automobile industry, delivering great results and improving efficiency during production.

They can be used for tasks such as processing cylinder heads and blocks, making oil sumps, creating transmission housings, and producing steering knuckles.

With their superior wear resistance, PCD tools help to ensure the accuracy of machining while reducing the costs associated with manufacturing.

Application

- 1

Cylinder head Process

- 2

Cylinder block

- 3

Oil Sump

- 4

Transmission Housing

- 5

Steering knuckle

Advantage

- 1

Extremely high wear resistance

- 2

Achieving high-precision machining

- 3

Increasing production efficiency, reducing manufacturing costs

For Electronics and new energy industries

Cutting tools are vital in electronics and renewable energy industries, enabling versatile and easy manufacturing processes. Their precision and efficiency meet demands while ensuring accuracy and quality for components. They also promote innovation, driving progress forward.

Application

- 1

Electronics

Precision machining for electronic components, PCBs, and packaging.

- 2

Solar energy

Processing solar panel components for optimized performance

- 3

Wind energy

Machining wind turbine parts for enhanced efficiency

- 4

Electric vehicles

Manufacturing battery control modules

Advantage

- 1

Versatility

Variety of tool types and specifications

- 2

Precision

Accurate machining control, reducing defects

- 3

Efficiency

High-speed, efficient processing for shorter production cycles

Case Studies

Tooling Solutions by Sundi

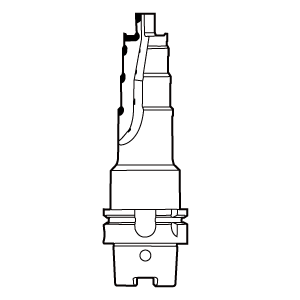

Custom PCD Reamers for Machining Steering Gear Housings

-

Custom Carbide Drills for Piston Hydraulic Pump Machining

"See the precision carbide drills engineered for hydraulic pump bores, guaranteeing superior concentricity and extended tool life for critical fluid components."

-

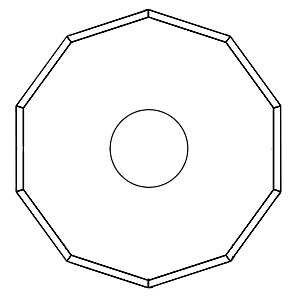

Custom Solid CBN Inserts for Brake Disc Turning

"See the robust solid CBN inserts engineered for brake discs, delivering consistent surface finish and high efficiency for mass production turning."

-

Custom PCD Face Mills for Aluminum Cylinder Heads

"Explore high-speed PCD milling solutions engineered for automotive engine parts, perfect for achieving burr-free surfaces and reducing cycle times in aluminum."

-

Custom PCD End Mills for Graphite Machining

"Explore the wear-resistant PCD solutions engineered for abrasive graphite, delivering exceptional edge retention and superior surface finish for precision EDM electrodes."

Turn to download page

Dear customer, on the download page, you can find the complete product manual, including company profile, introduction to peripheral materials, and more.

From Sundi Technical Articles

Explore innovative precision tooling insights on our Sundi Tools blog, where we leverage years of expertise to offer practical tips and the latest advancements. Our content is crafted to help you optimize your manufacturing processes and product design for industry-leading performance.

Wuxi Sundi Precision Tools Co.,LTD

- +86 18168312921

- +86 18168312921

- +86 18951588639

- info@sundicuttingtools.com

Our team is here to help you! We provide personalized solutions to meet your unique needs. Contact us to learn more.

still has hesitation ? It's time to talk

Certificate

Flexible Solutions Trusted Quality

Experience our dedication to customized services, responsive communication, and shared growth - forging a powerful alliance.

Shipping By

Secure Payment Options

The Tool life is around 10,000 holes, Cutting under liquid coolant on HASS machinie center .Good Job!

Joel Douglas CEO