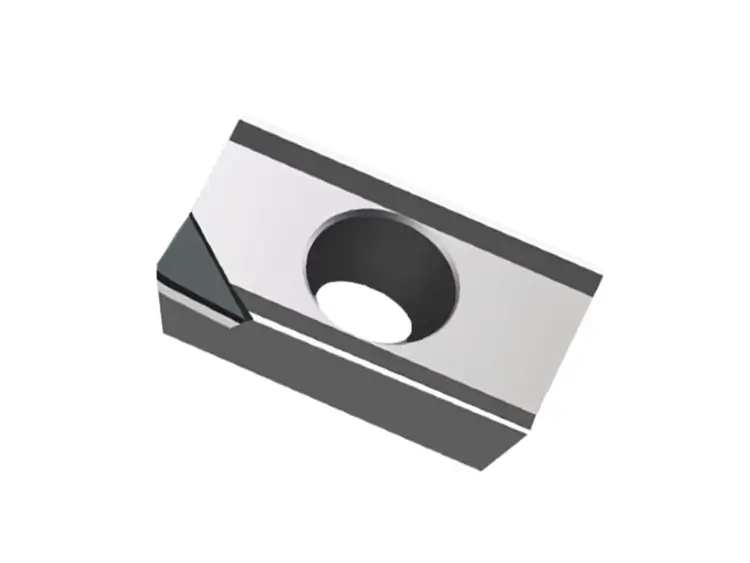

PCD Milling Inserts

Are you looking to reduce cycle times while maintaining pristine surface finishes in your milling operations?

Sundi PCD Milling Inserts are engineered to handle the high-speed demands of modern CNC machining centers. Unlike standard carbide, our Polycrystalline Diamond edges thrive under high RPMs, delivering a tool life extending 20x to 50x beyond conventional options. Whether for face milling engine blocks or shoulder milling aerospace components, Sundi ensures peak efficiency.

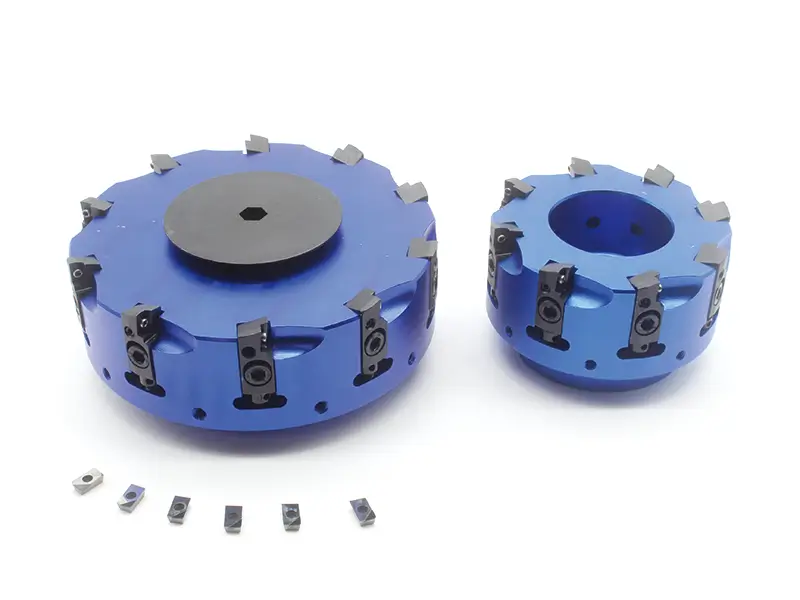

Comprehensive Milling Solutions

We provide a wide array of ISO-standard and custom PCD Milling Inserts compatible with most major face mill and end mill holders.

Face Milling (45° / 90°): High-efficiency inserts (e.g., SEHT, SEET) for rapidly flattening large surfaces like automotive casings.

Shoulder Milling (90°): Precision inserts (e.g., APKT, APMT) for creating true 90-degree walls and steps.

Copy & Profile Milling: Round inserts (e.g., RCHT, RPMT) for contouring complex 3D shapes in mold making.

Wiper Inserts: Special geometry inserts designed specifically to improve the final floor finish.

Target Materials for Milling

Sundi PCD Milling Inserts deliver the best ROI when applied to the following non-ferrous groups. Note: Not for use on Steel or Iron.

Automotive Aluminum: Ideal for milling cylinder heads, transmission housings, and EV battery trays.

Aerospace Components: Perfect for “hogging out” large structural parts from aluminum billets.

Copper Heatsinks: Creates burr-free fins and perfectly flat mounting surfaces.

Composite Materials: Cleanly mills carbon fiber and fiberglass without fraying the edges.

- High wear resistance

- Reduce the machine time

- Stable Performance

- Easy to use

The Sundi Advantage in PCD Milling

Milling is an “interrupted cutting” process that places unique stresses on tool edges. Sundi PCD Milling Inserts are specifically sintered to resist impact while maintaining extreme hardness.

-

Built for High-Speed Machining (HSM)

Time is money. Sundi PCD grades allow you to run at significantly higher surface feet per minute (SFM). This drastically increases your Material Removal Rate (MRR), allowing you to clear more aluminum in less time without sacrificing tool integrity.

-

Exceptional Surface Flatness & Finish

Achieve "mirror-like" results directly from the mill. Our inserts feature optimized Wiper geometries that smooth the workpiece surface as they cut. This often eliminates the need for secondary grinding or polishing operations, ensuring a surface roughness of Ra 0.4 or better.

-

Stability in Interrupted Cuts

Milling involves constant entry and exit from the material. Sundi’s premium PCD grade features a tough microstructure designed to absorb these shocks without chipping, preventing catastrophic failure even during heavy roughing passes.

Technical Specifications

Sundi PCD Milling Inserts are designed to fit standard cutter bodies, making the switch from carbide simple and cost-effective.

| Feature | Specification | Milling Benefit |

| Insert Standard | APKT / SEHT / TPGH / RCHT | Compatible with existing milling heads. |

| Cutting Edges | 1 or 2 PCD Tipped Corners | Economical options for different depths of cut. |

| Wiper Geometry | Available on request | Ensures superior surface finish on floors. |

| Grade | Fine / Medium / Coarse Grain | Optimized for Finishing or Roughing. |

| Material Suitability | Non-Ferrous Only | Specialized for Aluminum, Magnesium, Copper. |

Elevate Your Milling Performance

Don't let tool wear limit your production speed. Upgrade to Sundi PCD Milling Inserts for faster cycles, better finishes, and lower cost per part.

FAQ

Most frequent questions and answers

A: In aluminum applications, you can typically increase your cutting parameters by 300% to 500%. While carbide might be limited to 300-500 m/min, Sundi PCD remains stable at speeds exceeding 2000 m/min, drastically reducing cycle time per part.

A: No. Milling Cast Iron with PCD will result in rapid thermal and chemical wear. For milling ferrous materials like Cast Iron or Steel, we recommend our Sundi CBN (Cubic Boron Nitride) inserts, which are specifically formulated for hard ferrous milling.

A: A “Wiper” edge is a slightly flattened section on the insert corner. In face milling, it acts like a smoothing tool, wiping across the material surface to smooth out the feed marks (scallops), resulting in a superior, glass-like finish even at high feed rates.