CNC Turning: Basic Guide for Beginners

CNC Turning is a subtractive machining process where a CNC operator cuts spinning workpiece using a stationary tool. This method is important for modern manufacturing because it provides speed, precision, and ability to repeat cuts. We will cover the process, operations, materials, and design best practices.

How CNC Turning Works?

The fundamental process involves spinning the raw material while the cutting tool moves across its surface. This continuous action removes material to achieve the desired geometric shape.

Parts of a CNC Turning Machine

A central spindle holds and spins the material, securing it with a chuck. In turn, the cutting tools are mounted in a turret. The control unit directs all movements, using coolant and chip removal systems to maintain efficiency.

Types of Machines and Axes

Basic 2-axis lathes only control the tool in the X and Z directions. Next, multi-axis turning centres add live tooling and other C. Y, B axes. This allows the machine to perform both milling and drilling operations.

The Workflow from Design to Part

The process starts with a finished design in CAD. Secondly, you move the design into CAM software to generate the necessary tool paths. These paths become G code. The machine then reads this code to execute the physical cutting.

Common CNC Turning Operations

In CNC turning, you can make different cuts of basic and complex features. However, the question is What kind of parts can a CNC lathe make?

Straight and Rough Turning

First, you need to recognize that rough turning quickly removes excess material. It brings the diameter close to the final size. Then, you will perform straight turning to refine the surface and achieve the final, accurate dimensions and required smoothness.

Facing, Tapering, and Threading

Facing flattens the end of the part. It will ensure the surface is perfectly square to the axis. Furthermore, taper turning creates a cone shape on the workpiece. Moreover, threading accurately cuts screw threads onto the external or internal surfaces.

External vs Internal Turning

External turning shapes the outside diameter of the workpiece. Meanwhile, internal turning is also known as boring. In this process, you enlarge an existing hole inside the material.

Specialised Operations

Also, note that complex machines can perform operations like hard turning for materials that are extremely tough. These operations often use advanced tooling to achieve difficult geometries.

What Are the Common Tool Types Used in CNC Turning?

CNC turning uses particular tools to shape metal and plastic parts. These tools are often small cutting tips called inserts.

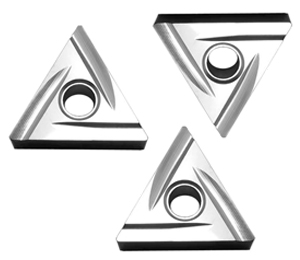

Carbide Inserts

Carbide inserts are the most common cutting tools. They are very hard and work well for many materials. They handle most general turning jobs.

High Speed Steel Tools

These tools are used for softer materials. They are cheaper and you can sharpen them easily. They are great for small runs or complex shapes.

Cermet Inserts

These inserts are ceramic and metal mixtures. They give a very smooth finish to the surface. They work best on steel and stainless steel.

PCD Inserts

PCD inserts use industrial diamond tips. They are extremely hard. You must use them for cutting very tough materials. They are best for non-ferrous metals like aluminum or copper.

CBN Inserts

CBN inserts are the second hardest material after diamond. You use them for cutting hardened steel and superalloys. They handle very high heat and wear.

These inserts are made entirely of the CBN material, not just the tip. They last longer and perform better under heavy stress. They are necessary for extreme machining tasks on hard metals.

What Materials you can use for CNC Turning?

The best choice depends on your application. But many materials work well if you hold and place them rght. So What is the easiest metal to machine on a lathe?

Common Turnable Materials

Standard materials for CNC turning include aluminium 6061, different steels and brass, and Nylon. You should choose a material based on its final application, not just how easy it is to cut.

Anoher important point is that you must check the material’s machinability. It affects chip formation and tool wear. Another important thing is the material’s rigidity to prevent the part from bending during a long cut.

Advantages and Limitations of CNC Turning

Turning is efficient for rotational parts but has specific cost and geometric limits. When is turning better than milling?

Advantages

CNC turning is good at high precision and excellent repeatability. The process consistently achieves tight dimensional tolerances, often down to 0.005 mm.

Limitations

Consequently, turning is best for round parts and struggles with block geometries. The initial investment in a multi axis machine, tool setup, and programming is a significant upfront cost.

Turning vs Milling

You prefer turning for parts requiring fast material removal on rotational surfaces and OD/ID. However, milling is good for complex, prismatic shapes.

CNC Turning Applications

Turning is a highly versatile process used across almost every industry to solve specific dimensional problems. Where is CNC turning used most?

Automotive and Industrial Shafts

First, you need to consider the automotive industry’s constant need for precise shafts, axles, and pins. Turning creates rotational components that can face high stress and high RPMs. It is crucial for smooth engine and gearbox operation.

Medical Implants and Devices

After that, look at medical and dental devices. Turning ensures the high accuracy and smooth finish required for sterile parts like bone screws, custom fittings, and small instruments. These parts often require tight tolerances on materials like stainless steel or titanium.

Aerospace Fasteners and Connectors

Next, turning is key in aerospace for producing thousands of high-strength fasteners and connectors. These parts demand extreme weight consistency and material purity. The repeatability of turning guarantees every part meets strict flight safety standards.

Design Considerations and Best Practices

Design choices heavily influence the cost and quality of your final component.

Tool Accessibility and Fixturing

First, you need to ensure the cutting tool can reach all surfaces without colliding with the chuck or machine components. Tool size limits the minimum diameter and maximum depth of internal features like bores.

Feature Stability

Then, you should avoid designing very long, slender parts or thin sections. These features increase the risk of the part vibrating or deforming, which requires slowing the entire machining process down for quality control.

Parameter Optimization

Next, focus on optimising the spindle speed, feed rate, and depth of cut. This combination ensures the best possible surface finish and helps reduce tool wear and energy consumption.

Practical Collaboration

Finally, make sure to verify all toolpaths and material offsets with your machining partner before production starts. Early prototyping saves cost and confirms the feasibility of all complex design elements.

Conclusion

CNC turning is a fast, accurate process for creating rotational components. You should choose this method when high precision and volume production are your main requirements.

FAQs

Q: What is CNC turning?

A:CNC turning is a way to make round parts. The machine spins the material fast. A fixed cutting tool moves along the spinning material to remove material and shape it.the length of the board.

Q: What is a CNC turning machine?

A: It is a machine that uses computer control to automate the turning process. The machine holds the material and rotates it. The computer guides the cutting tool precisely to make the part.

Q: How to turn a 3D printer into a CNC?

A: You need to change the 3D printer’s head. Replace the plastic extruder with a small cutting tool, ery similar to rotary tool. Then, you must change the control software to use G code for cutting instead of printing.

Q: How to turn a picture into a CNC carving?

A: First, you must use special cam software. This software traces the picture and turns it into 3D height data. Then, the software makes the machine instructions for the CNC to carve the design.

Q: How to use G41 and G42 in CNC turning?

A: G41 and G42 are codes for cutter radius compensation. G41 moves the tool path to the left of the programmed line. G42 moves the tool path to the right.