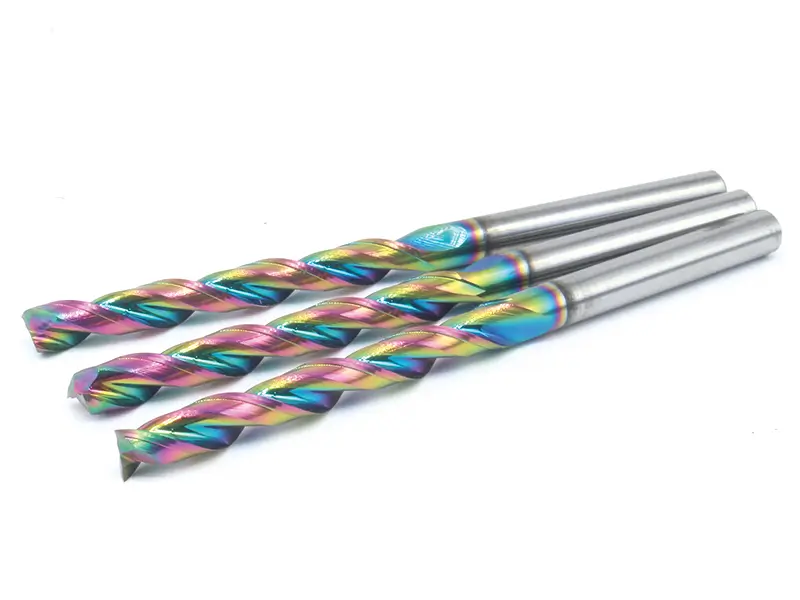

Flat Bottom Drill

At Sundi Cutting Tools, our Carbide Flat Bottom Drills are designed for exceptional performance in drilling precise, flat-bottomed holes, especially on angled or curved surfaces. With a 180° point angle, these drills can create perfectly flat-bottomed holes without the need for additional finishing with end mills, offering a streamlined and efficient drilling process.

Benefits:

Increased Efficiency: By eliminating the need for secondary finishing operations, the carbide flat bottom drill improves machining efficiency and reduces the number of tools needed.

High-Performance Cutting: The dual cutting edges enable faster feeds and higher performance, enhancing productivity while ensuring smooth, precise hole formation.

Extended Tool Life: Made from durable carbide material, these drills provide long-lasting performance, reducing tool wear and improving cost-effectiveness over time.

Superior Surface Finish: Achieves flat-bottomed holes with minimal burrs and an excellent surface finish, perfect for precision machining.

Looking for an efficient and reliable solution for flat-bottom drilling?

Contact Sundi Cutting Tools today to learn more about our Carbide Flat Bottom Drills and how they can enhance your machining operations.

- High wear resistance

- Reduce the machine time

- Stable Performance

- Easy to use

The Features of Carbide Flat Bottom Drill

Ideal for Angled and Curved Surfaces

The 180° point angle allows for the creation of flat-bottomed holes, making these drills perfect for applications where traditional drills or end mills may struggle.

Dual Cutting Edges

Featuring two effective cutting edges at the center, these drills provide enhanced feed rates and improved cutting performance.

Versatile Material Compatibility

Perfect for machining a variety of materials, including non-ferrous metals, steel, cast iron, stainless steel, and high-temperature alloys.

High Precision and Low Vibration

Designed to minimize vibration and ensure excellent centering accuracy during subsequent drilling operations, delivering high-quality results.

Two-in-One Solution

The unique design eliminates the need for an additional 180° end mill for flat-bottom drilling, combining two processes into one tool. This innovation simplifies your machining workflow, saving time and improving overall production efficiency.