Straight Flute Reamer

At Sundi Cutting Tools, our Straight Flute Reamers are versatile, high-performance tools designed for through holes and short blind holes. Known for their simple structure, low cost, and easy re-sharpening, these reamers provide excellent dimensional accuracy, rigidity, and stability, making them ideal for use in industries such as general machining, automotive, and precision assembly.

Typical Applications:

General Machining: Final processing of bearing holes, positioning holes, and bolt holes, where high dimensional consistency is crucial.

Automotive Manufacturing: Reaming through holes in engine blocks, transmission housings, and other parts made of cast iron and similar materials.

Precision Assembly: Precision finishing of tool fixtures, mold guide bushings, and other components requiring H7 tolerance.

Manual Maintenance: On-site hole reaming work, ideal for small-batch repairs. The simplicity and ease of use make it suitable for quick field operations.

Looking for a simple, reliable reaming solution?

Sundi Cutting Tools offers Straight Flute Reamers that combine cost-effectiveness with precision, making them the perfect choice for regular reaming tasks. If your project involves deep blind holes, cross holes, or processing plastic materials, consider spiral flute reamers for better chip removal and surface quality.

- High wear resistance

- Reduce the machine time

- Stable Performance

- Easy to use

The Features of Straight Flute Reamer

Cost-Effective and Easy to Maintain

The simple design makes these reamers affordable and cost-effective. Their low manufacturing cost and straightforward re-sharpening process—only requiring chamfering of the cutting edges—ensure that the long-term maintenance costs are minimal.

Ease of Use

With stable cutting forces and no axial forces caused by helical flutes, straight flute reamers are easy to operate and perfect for beginners. They are ideal for both manual and semi-automatic machining, simplifying the reaming process for all skill levels.

Versatility

Straight flute reamers are adaptable to a wide range of materials, particularly brittle materials like cast iron and brass, and are ideal for high-precision hole finishing.

Effective Chip Removal for Through Holes

These reamers are highly effective at chip removal in through holes, while they may require extra care for blind holes due to chip accumulation.

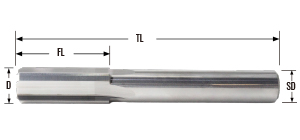

Specifications of Straight Flute Reamer

| Tech data | |

|---|---|

| Grade | SRA/SRB |

| Coating | DLC/AlTisiN/TiALCrN |

| Coating color | Colored/Bronze/BLACK |

| In Store | Yes |

| How to order | Contact Us |

| Download all Specification | Download |

Specification and Application

| Order No. | D [mm] | FL [mm] | TL [mm] | SD h6 [mm] |

|---|---|---|---|---|

| SRA-D4.0 | 4.0 | 20 | 56 | 3.5 |

| SRA-D4.5 | 4.5 | 22 | 63 | 4.0 |

| SRA-D5.0 | 5.0 | 22 | 63 | 4.0 |

| SRA-D5.5 | 5.5 | 22 | 63 | 5.0 |

| SRA-D6.0 | 6.0 | 22 | 63 | 5.0 |

| SRA-D6.5 | 6.5 | 22 | 63 | 5.0 |

| SRA-D7.0 | 7.0 | 25 | 71 | 6.0 |

| SRA-D7.5 | 7.5 | 25 | 71 | 6.0 |

| SRA-D8.0 | 8.0 | 25 | 71 | 6.0 |

| SRA-D8.5 | 8.5 | 25 | 71 | 8.0 |

| SRA-D9.0 | 9.0 | 25 | 71 | 8.0 |

| SRA-D9.5 | 9.5 | 25 | 71 | 8.0 |

| SRA-D10.0 | 10.0 | 25 | 71 | 8.0 |

| SRA-D10.5 | 10.5 | 28 | 80 | 10.0 |

| SRA-D11.0 | 11.0 | 28 | 80 | 10.0 |

| SRA-D11.5 | 11.5 | 28 | 80 | 10.0 |

| SRA-D12.0 | 12.0 | 28 | 80 | 10.0 |

| SRA-D12.5 | 12.5 | 28 | 80 | 10.0 |

| SRA-D13.0 | 13.0 | 28 | 80 | 10.0 |

| SRA-D13.5 | 13.5 | 32 | 90 | 12.5 |

| SRA-D14.0 | 14.0 | 32 | 90 | 12.5 |

| SRA-D14.4 | 14.5 | 32 | 80 | 12.5 |

| SRA-D15.0 | 15.0 | 32 | 90 | 12.5 |

| SRA-D15.5 | 15.5 | 32 | 90 | 12.5 |

| SRA-D16.0 | 16.0 | 32 | 90 | 12.5 |

| SRA-D16.5 | 16.5 | 32 | 90 | 12.5 |

| SRA-D17.0 | 17.0 | 32 | 90 | 16.0 |

| SRA-D17.5 | 17.5 | 36 | 100 | 16.0 |

| SRA-D18.0 | 18.0 | 36 | 100 | 16.0 |

| SRA-D18.5 | 18.5 | 36 | 100 | 16.0 |

| SRA-D19.0 | 19.0 | 36 | 100 | 16.0 |

| SRA-D19.5 | 19.5 | 36 | 100 | 16.0 |

| SRA-D20.0 | 20.0 | 36 | 100 | 16.0 |

| Order No. | D [mm] | FL [mm] | TL [mm] | SD h6 [mm] |

|---|---|---|---|---|

| SRB-D4.0 | 4 | 20 | 50 | 4 |

| SRB-D5.0 | 5 | 22 | 60 | 4 |

| SRB-D6.0 | 6 | 22 | 60 | 6 |

| SRB-D7.0 | 7 | 25 | 70 | 6 |

| SRB-D8.0 | 8 | 25 | 70 | 6 |

| SRB-D9.0 | 9 | 25 | 70 | 6 |

| SRB-D10.0 | 10 | 25 | 70 | 6 |

| SRB-D11.0 | 11 | 28 | 80 | 6 |

| SRB-D12.0 | 12 | 28 | 80 | 6 |

| SRB-D13.0 | 13 | 28 | 80 | 6 |

| SRB-D14.0 | 14 | 32 | 90 | 6 |

| SRB-D15.0 | 15 | 32 | 90 | 6 |

| SRB-D16.0 | 16 | 32 | 90 | 6 |

| SRB-D17.0 | 17 | 32 | 90 | 6 |

| SRB-D18.0 | 18 | 36 | 100 | 6 |

| SRB-D19.0 | 19 | 36 | 100 | 6 |

| SRB-D20.0 | 20 | 36 | 100 | 6 |