Carbide Taper Reamer

At Sundi Cutting Tools, our Carbide Taper Reamers are high-precision tools specifically designed for machining tapered holes, such as taper pins, Morse taper holes, and centerline taper holes. Made from solid carbide, these reamers feature cutting edges distributed along the taper’s generatrix, allowing for efficient, one-pass machining of tapered holes that meet strict taper tolerances. The key advantages are high taper accuracy, fast machining efficiency, and excellent wear resistance, making them ideal for precision assembly and positioning applications.

Typical Applications:

Precision Assembly: Used in mold making, tooling, and machinery where precise tapering is crucial for proper alignment and fit.

Automotive: Ideal for machining precision taper holes in engine components, gearboxes, and transmission systems.

Aerospace: Essential for high-precision taper hole finishing in aerospace parts, ensuring accurate alignment for fittings and assemblies.

General Manufacturing: Suitable for a wide range of industries requiring reliable, efficient machining of tapered holes for assembly, positioning, and alignment.

Looking for efficient and accurate taper hole reaming solutions?

Contact Sundi Cutting Tools today to learn more about our Carbide Taper Reamers and how they can improve your machining efficiency and precision.

- High wear resistance

- Reduce the machine time

- Stable Performance

- Easy to use

The Features of Carbide Taper Reamer

High Taper Accuracy

The rigid carbide construction ensures minimal deformation during the cutting process, with the calibrated edges guaranteeing consistent taper accuracy. Class 1 precision reamers meet the centering requirements for spindle taper holes with exceptional precision.

Long Tool Life and Cost-Effective

With 8-12 times the wear resistance of HSS, carbide taper reamers offer extended tool life, capable of processing tens of thousands of workpieces per tool. This makes them highly suitable for mass production, with significantly lower long-term operating costs.

Outstanding Machining Efficiency

The carbide taper reamer can complete the entire taper hole finishing process in a single pass, eliminating the need for step-by-step cutting. This results in 40% faster machining efficiency compared to HSS taper reamers, thanks to the carbide material's superior wear resistance, which allows for higher cutting speeds.

Versatile Compatibility

Ideal for machining 1:50, Morse taper, and other standard taper holes, these reamers are also available in custom non-standard tapers to meet the unique positioning and assembly needs of different industries.

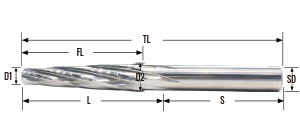

Specifications of Carbide Taper Reamer

Specification and Application

| Tech data | |

|---|---|

| Grade | SRE |

| Coating | DLC/AlTisiN/TiALCrN |

| Coating color | Colored/Bronze/BLACK |

| In Store | Yes |

| How to order | Contact Us |

| Download all Specification | Download |

| Order No. | D1 h7 [mm] | D2 [mm] | FL [mm] | S [mm] | L [mm] | TL [mm] | SD h6 [mm] |

|---|---|---|---|---|---|---|---|

| SRE-001 | 4.0 | 8.0 | 40 | 50 | 55 | 105 | 6.0 |

| SRE-002 | 6.0 | 11.0 | 50 | 50 | 65 | 115 | 10.0 |

| SRE-003 | 8.0 | 14.0 | 60 | 50 | 75 | 125 | 12.0 |

| SRE-004 | 10.0 | 18.0 | 80 | 50 | 95 | 145 | 16.0 |

| SRE-005 | 4.0 | 6.0 | 40 | 50 | 55 | 105 | 6.0 |

| SRE-006 | 6.0 | 8.8 | 50 | 50 | 65 | 115 | 8.0 |

| SRE-007 | 8.0 | 11.0 | 60 | 50 | 75 | 125 | 10.0 |

| SRE-008 | 10.0 | 14.0 | 80 | 50 | 95 | 145 | 12.0 |

| SRE-009 | 4.0 | 5.4 | 40 | 50 | 55 | 105 | 5.0 |

| SRE-010 | 6.0 | 7.7 | 50 | 50 | 65 | 115 | 6.0 |

| SRE-011 | 8.0 | 10.0 | 60 | 50 | 75 | 125 | 10.0 |

| SRE-012 | 10.0 | 12.7 | 80 | 50 | 95 | 145 | 12.0 |

| SRE-013 | 4.0 | 4.8 | 40 | 50 | 55 | 105 | 4.0 |

| SRE-014 | 6.0 | 7.0 | 50 | 50 | 65 | 115 | 6.0 |

| SRE-015 | 8.0 | 9.2 | 60 | 50 | 75 | 125 | 8.0 |

| SRE-016 | 10.0 | 11.6 | 80 | 50 | 95 | 145 | 10.0 |