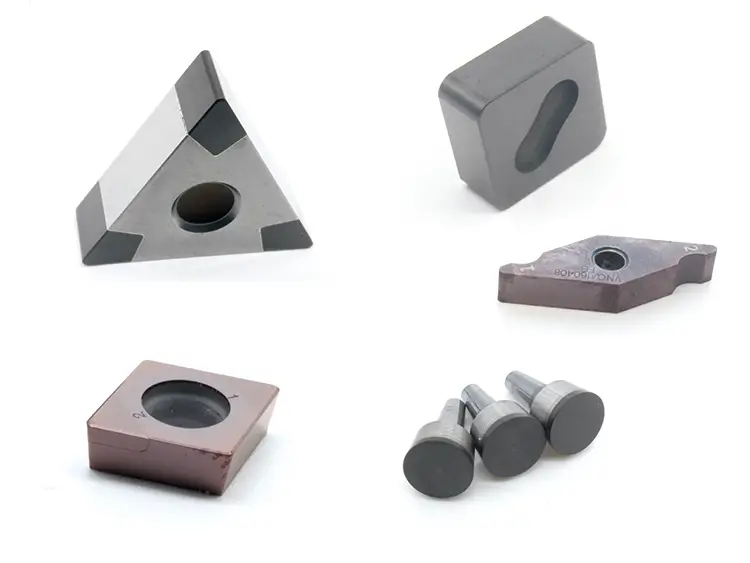

Custom CBN Turning Inserts

Standard CBN inserts are designed for general applications, but tough materials demand specialized solutions.

Sundi Custom CBN Inserts are engineered to optimize your specific “Hard Turning” process. Whether you need a complex profile to replace a grinding operation, or an advanced Coated CBN grade to survive extreme heat in dry machining, our engineering team transforms your challenges into a high-performance solution.

Our Customization Capabilities

We specialize in Non-Standard CBN solutions for automotive, wind energy, and heavy equipment industries.

Profile & Form Tools: CBN inserts ground to match the inverse shape of your hardened shaft or bearing race.

Combination Tools: Inserts that perform turning and back-chamfering simultaneously to reduce cycle time.

Heavy Duty Solid CBN: Custom large-size Solid CBN inserts for roughing Cast Iron rolls or Slurry Pumps.

Wiper Geometries: Custom Wiper designs to double your feed rate while maintaining a mirror finish.

From Concept to Hard Part: Our Process

We follow a strict protocol to ensure your custom CBN tool performs right out of the box.

Application Audit: We analyze your workpiece material (e.g., D2, 8620, Bearing Steel), Hardness (HRC), and machining conditions (Continuous vs. Interrupted).

Tool Design: Sundi engineers calculate the optimal cutting geometry and edge preparation to prevent crater wear and fracture.

Precision Fabrication: Using advanced Laser and Grinding technology, we shape the CBN blank to micron-level precision.

Inspection: 100% verification of profile accuracy and edge integrity before shipment.

- High wear resistance

- Reduce the machine time

- Stable Performance

- Easy to use

Why Choose Sundi Custom CBN?

In hard turning, rigidity and edge preparation are everything. We customize every aspect of the tool to survive the extreme forces of machining hardened materials.

-

1. The "Grinding Replacement" Strategy

Why grind when you can turn? We design custom CBN form tools that machine complex contours, chamfers, and radii in a single pass. This allows you to achieve grinding-quality tolerances and finishes (Ra 0.4) on your lathe, eliminating expensive and slow grinding setups.

-

2. Advanced Coated CBN Technology

We don't just offer bare CBN. We provide Custom Coated CBN options (TiN, TiAlN, AlCrN) to boost performance. Coatings act as a thermal barrier, reducing crater wear in high-speed continuous cutting, and the distinctive gold/grey colors make it easier for operators to identify used edges.

-

3. Optimized Substrates & rigidity

Vibration kills CBN. For deep bore hard turning or long overhangs, we design custom carbide substrates with maximum thickness and specific shapes to dampen vibration, ensuring the insert remains stable even under high cutting pressure.

Start Your Custom CBN Project Today

Unlock the efficiency of hard part machining with tools designed specifically for your process. Send us your blueprints and let Sundi engineer a Custom CBN Solution today.

FAQ

Most frequent questions and answers

A: Yes. This is known as “Hard Turning.” By using a high-precision Custom CBN insert, you can achieve surface finishes of Ra 0.2 and tolerances of IT6. This is significantly faster and cheaper than grinding, and it creates compressive residual stress which improves part fatigue life.

A: Besides the part drawing, the most critical information is the Material Hardness (HRC) and whether the cut is Continuous or Interrupted. This dictates the CBN grade selection and the edge preparation (Edge Prep) design.

A: Typically 2 to 3 weeks after drawing approval. We understand that production lines cannot stop, so we also offer expedited services for urgent tooling needs.