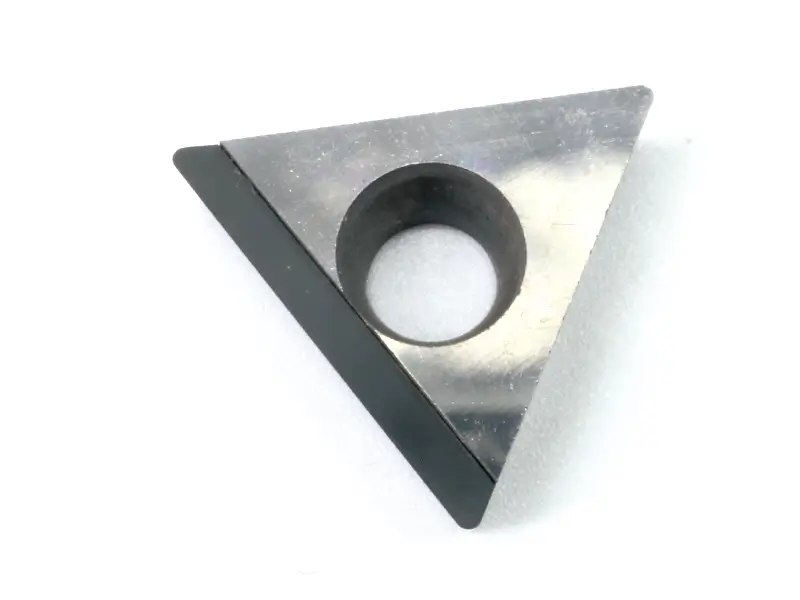

PCD Full Edge Turning Inserts

Standard PCD inserts only have a small diamond tip, limiting your depth of cut to just a few millimeters. When you need to remove massive amounts of material or perform wide plunge cuts, you need a bigger edge.

Sundi PCD Full Edge Inserts feature a solid strip of Polycrystalline Diamond brazed along the entire cutting edge (Full Length). This design releases the full potential of your lathe, allowing for deep roughing passes and extended tool life that standard tipped inserts simply cannot match.

Target Applications

Sundi Full Edge PCD Inserts are the secret weapon for specific high-volume industries.

Aluminum Roll Turning: Machining large printing rolls or film rollers where a seamless, long continuous cut is required.

Heavy Billet Roughing: Rapidly reducing the diameter of large aluminum or copper bars.

Wide Chamfering: Creating large bevels in one pass without stepping.

Commutator Turning: Shaving copper commutators in electric motors where edge consistency is vital.

- High wear resistance

- Reduce the machine time

- Stable Performance

- Easy to use

Why Choose Sundi Full Edge PCD Tools?

The “Full Edge” design transforms how you machine aluminum and copper. It bridges the gap between a standard turning tool and a heavy-duty forming tool.

-

1. Unlimited Depth of Cut (High DOC)

With a standard insert, burying the tool past the diamond tip leads to catastrophic carbide failure. With Sundi Full Edge, the diamond extends along the entire flank (e.g., 11mm or 16mm). This allows you to take aggressive deep cuts in a single pass, drastically removing material from billets or large castings.

-

2. Superior Heat Dissipation

Diamond is the best thermal conductor known to man. By having a massive volume of PCD along the entire edge, heat is drawn away from the cutting zone much faster than with a tiny tip. This results in lower cutting temperatures and significantly longer tool life, even under heavy load.

-

3. Versatile "Plunge" & Profiling Capability

The continuous edge allows for unique machining strategies. You can perform plunge turning (feeding radially like a grooving tool) or create wide chamfers and profiles without worrying about running out of diamond edge length.

Technical Specifications

| Tech Data | |

|---|---|

| Type | ISO Indexable PCD inserts |

| Angle | Positive/ negative |

| PCD Grade | PCD 850/ PCD 010/PCD 025/PCD302 |

| Tolerance | G/M |

| Work piece material | Aluminum and aluminum alloys Copper, brass and bronze alloys Carbon Fiber Graphite composites Reinforced plastics Ceramic Wood Fiberglass Composites Fiber Reinforced Plastics (FRP) Tungsten Carbide |

| Shape | Designation | D1 [mm] | D2 [mm] | S [mm] | R [mm] |

|---|---|---|---|---|---|

| TCGW090202 | 5.56 | 2.5 | 2.38 | 0.2 |

| TCGW110204 | 6.35 | 2.8 | 2.35 | 0.4 | |

| TCGW16T308 | 9.525 | 4.4 | 3.97 | 0.8 | |

| CCGW060204 | 6.35 | 2.8 | 2.38 | 0.4 |

| CCGW09T308 | 9.525 | 4.4 | 3.97 | 0.4 | |

| CCGW120412 | 12.7 | 5.5 | 4.76 | 1.2 | |

| SCGW09T304 | 9.525 | 4.4 | 3.97 | 0.4 |

| SCGW120408 | 12.7 | 5.5 | 4.76 | 0.8 |

Unleash the Full Potential of PCD

Stop limiting your productivity with tiny diamond tips. Switch to Sundi PCD Full Edge Inserts for heavy-duty material removal and unmatched tool life.

FAQ

Most frequent questions and answers

A: A “Tipped” insert has a small diamond corner welded on, typically allowing a depth of cut of only 0.5mm to 1.0mm. A Sundi Full Edge insert has diamond along the entire side, allowing you to cut as deep as the insert is long (e.g., 10mm deep) without damaging the tool body.

A: Yes, absolutely. This is a huge cost benefit. Because there is so much diamond material along the edge, Sundi Full Edge inserts can often be reground multiple times, restoring them to “like-new” performance for a fraction of the cost of a new insert.

A: They excel at both. While designed for heavy cutting capacity, the continuous sharp diamond edge produces excellent surface finishes. Many customers use them for “Wiper” style finishing passes on long shafts.