Solid Carbide Drills

Introduction Of Carbide Drills Bits

Carbide drill bits, made with tungsten carbide as the core material, offer superior hardness and wear resistance compared to HSS. Whether for deep-hole drilling in engine blocks, precision drilling of titanium alloy parts in aerospace, or efficient cutting of high-strength materials like tool steels, carbide drill bits provide stable cutting performance, precise dimensional control, and long-lasting durability to enhance production efficiency.

At Sundi, we specialize in delivering custom drill bit solutions backed by our engineering expertise and industry best practices. Our carbide drill bits are designed for high precision and efficiency, making them the ideal choice for various drilling applications. No matter the order size, we provide the best solutions to improve your production efficiency.

PRODUCTS

Sundi offers a wide range of carbide drill bits tailored for specific materials or applications. Whether you need versatile, high-volume, or micro-machining solutions, or deep-hole drilling tools, we provide both standard and custom carbide drill bits at competitive prices.

Carbide Drill For Hard Materials

General-Purpose Twist Drill

CVD Drill For CFRP

3 Flutes Drill

Straight Flute Drill

Step Drill

Spot Drill

Center Drill

Flat-Bottom Drill

Deep Hole Twist Drill

Carbide Micro Drill

Structural Introduction of Solid Carbide Drill Bits Sets

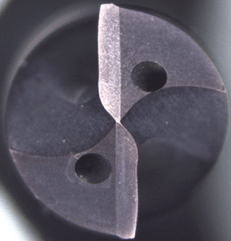

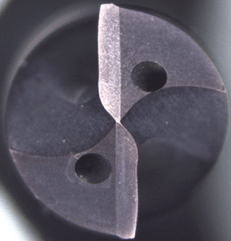

Drill bit cutting edge Design

- 1

The straight main cutting blade

- 2

Smooth and big radius

- 3

Sharp drill point

- 4

Curve chip room make shorter chips

- 5

Big chip room

High-Grade Tungsten Carbide Material

We select premium tungsten carbide materials tailored for machining steel, cast iron, non-ferrous metals such as aluminum and copper, as well as high-temperature alloys, offering superior wear resistance and exceptional stability.

Types of Coatings for Our Solide Carbide Drill Bits

| Coating | Color | Coating hardness HIT [GPa] | Max temperature | Friction Coefficient | Optimal Applications | compatibility |

|---|---|---|---|---|---|---|

| DLC | Black/iridescence | 65 | 450° | < 0.10 | Non-ferrous metals | ★ |

| CVD Diamond-Coated | dark gray | 80 - 100 | 600° | - | Composite materials,Graphite, ceramics | ★ |

| AlTiN | gray | 35 +/-3 | 1000° | - | General-Purpose | ★★★ |

| AlTiSiN | bronze | 38 +/-1 | 1000° | - | Hard Materials | ★★ |

DLC

CVD Diamond

AlTiN

AlTiSiN

Specification of Solid Carbide Drill Bits Sets

Workpiece Material

| Coolant | Work piece material | Diameter | Length of flute |

|---|---|---|---|

| for steel / cost iron/ special Alloys | D3.0-D20 | 3D |

| D3.0-D20 | 5D | ||

| D3.0-D20 | 8D | ||

| for steel / cost iron | D3.0-D20 | 3D |

| D3.0-D20 | 5D | ||

| D3.0-D20 | 8D |

Workpiece Material

| Coolant | Work piece material | Diameter | Length of flute |

|---|---|---|---|

| for aluminum/ cooper/ nonferrous metal | D3.0-D20 | 3D |

| D3.0-D20 | 5D | ||

| D3.0-D20 | 8D | ||

| for aluminum/ cooper/ nonferrous metal | D3.0-D20 | 3D |

| D3.0-D20 | 5D | ||

| D3.0-D20 | 8D |

User Case of Soild Carbide Drill Bits Sets

| User Application | |

|---|---|

| Workpice Material | 42CrMo |

| Application | Drill |

| Cutting Speed | 80m/min |

| Feed | 980mm/min |

| Dill deep | 14mm |

| Coolnat | emulsion |

| Device | HAAS |

| User Application | |

|---|---|

| Workpice Material | SUS304 |

| Application | Drill |

| Cutting Speed | 70m/min |

| Feed | 943mm/min |

| Dill deep | 24mm |

| Coolnat | emulsion |

| Device | BT50 |

FAQ

HSS (High-Speed Steel) drills are versatile and commonly used for drilling a variety of materials, such as steel, wood, and plastics. They are more affordable compared to carbide drills and are suitable for less demanding applications. On the other hand, carbide drills are made of a tougher material that can withstand higher temperatures, making them ideal for drilling hard materials such as stainless steel, titanium, and other alloys. Carbide drills offer superior performance and longer tool life, but they come at a higher cost.

For more details, you can visit Choosing Between HSS and Carbide Drill Bits.

Yes, carbide drills are capable of drilling through hardened steel. Due to their hardness and heat resistance, carbide drills can effectively cut through tough materials like hardened steel without losing their edge. However, it’s essential to ensure proper drilling parameters (e.g., speed, feed rate, and coolant) to prevent excessive wear or breakage.

While carbide tools are known for their durability and performance, they come with some drawbacks. The main disadvantage is their brittleness — carbide tools are more prone to chipping or breaking if not handled correctly or if they encounter shock loads. They also tend to be more expensive than their HSS counterparts. Furthermore, carbide tools require precise machining conditions and careful handling during installation and operation.

Wuxi Sundi Precision Tools Co.,LTD

- +86 18168312921

- +86 18168312921

- +86 18951588639

- info@sundicuttingtools.com

Our team is here to help you! We provide personalized solutions to meet your unique needs. Contact us to learn more.