Spiral Flute Reamer

At Sundi Cutting Tools, our Spiral Flute Reamers are specifically designed for plastics, deep blind holes, and complex hole geometries. With superior chip removal capabilities and the ability to handle interrupted cutting, these reamers are the perfect solution for challenging materials and applications that traditional straight flute reamers struggle with.

Typical Applications:

Automotive Components: Reaming engine crankshaft holes, connecting rod holes (aluminum alloy / alloy steel, blind holes + deep holes), and transmission gear shaft holes (interrupted cutting surfaces).

Aerospace: Machining titanium alloy fuselage frame holes and aluminum alloy wing connection holes (deep blind holes + high precision).

Mold Manufacturing: Reaming injection mold guide bush holes (with pre-machined cooling slots, requires interrupted reaming) and die-casting mold core holes (aluminum alloy material, preventing chip clogging).

General Machinery: Reaming stainless steel valve body holes and hydraulic cylinder barrel holes (long chip materials + deep blind holes).

Looking for superior performance in challenging reaming tasks?

Contact Sundi Cutting Tools today to learn more about our Spiral Flute Reamers and how they can enhance your machining operations in deep hole reaming, complex hole shapes, and plastics machining.

- High wear resistance

- Reduce the machine time

- Stable Performance

- Easy to use

The Features of Spiral Flute Reamer

Excellent Chip Removal

The deep spiral flutes and spiral cutting edges efficiently curl long chips into a spring-like shape and smoothly eject them, preventing chip buildup and damage to hole walls. This makes them ideal for blind hole and deep hole applications.

Ideal for Complex Hole Geometries

The axial force provided by the spiral flutes ensures stable cutting, making the reamer ideal for cross-holes, step holes, and holes with pre-machined slots. It prevents "tool jump" and dimensional deviations, ensuring high accuracy.

High-Speed Machining Compatibility

The rigid design and coating make these reamers suitable for high-speed cutting (100–300 m/min), significantly improving production efficiency compared to straight flute reamers, which typically operate below 150 m/min.

Smooth Cutting Process:

The spiral design generates axial force, leading to smoother cutting operations, reducing the risk of chatter or edge chipping. This allows for stable and precise machining, even on complex hole shapes.

Perfect for Plastic Materials

For soft steel, aluminum alloys, and other materials prone to long chips, spiral flute reamers achieve excellent surface finishes with Ra 0.4–1.6 μm smoothness, outperforming straight flute reamers.

Enhanced Vibration Resistance

The spiral structure distributes cutting forces, reducing vibrations and making these reamers ideal for machining thin-walled parts and long shafts, ensuring minimal deformation during the reaming process.

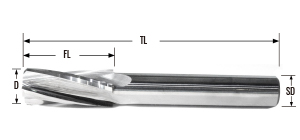

Specifications of Spiral Flute Reamer

Specification and Application

| Tech data | |

|---|---|

| Grade | SRD |

| Coating | DLC/AlTisiN/TiALCrN |

| Coating color | Colored/Bronze/BLACK |

| In Store | Yes |

| How to order | Contact Us |

| Download all Specification | Download |

| Order No. | D [mm] | FL [mm] | TL [mm] | SD h6 [mm] |

|---|---|---|---|---|

| SRD-D4.0 | 4.0 | 20 | 56 | 10.0 |

| SRD-D4.5 | 4.5 | 22 | 63 | 10.0 |

| SRD-D5.0 | 5.0 | 22 | 63 | 12.5 |

| SRD-D5.5 | 5.5 | 22 | 63 | 12.5 |

| SRD-D6.0 | 6.0 | 22 | 63 | 12.5 |

| SRD-D6.5 | 6.5 | 22 | 63 | 12.5 |

| SRD-D7.0 | 7.0 | 25 | 71 | 12.5 |

| SRD-D7.5 | 7.5 | 25 | 71 | 12.5 |

| SRD-D8.0 | 8.0 | 25 | 71 | 12.5 |

| SRD-D8.5 | 8.5 | 25 | 71 | 16.0 |

| SRD-D9.0 | 9.0 | 25 | 71 | 16.0 |

| SRD-D9.5 | 9.5 | 25 | 71 | 16.0 |

| SRD-D10.0 | 10.0 | 25 | 71 | 16.0 |

| SRD-D10.5 | 10.5 | 28 | 80 | 16.0 |

| SRD-D11.0 | 11.0 | 28 | 80 | 16.0 |

| SRD-D11.5 | 11.5 | 28 | 80 | 16.0 |

| SRD-D12.0 | 12.0 | 28 | 80 | 80 |

| Order No. | D [mm] | FL [mm] | TL [mm] | SD h6 [mm] |

|---|---|---|---|---|

| SRD-D4.0 | 4.0 | 20 | 56 | 3.5 |

| SRD-D4.5 | 4.5 | 22 | 63 | 4.0 |

| SRD-D5.0 | 5.0 | 22 | 63 | 4.0 |

| SRD-D5.5 | 5.5 | 22 | 63 | 5.0 |

| SRD-D6.0 | 6.0 | 22 | 63 | 5.0 |

| SRD-D6.5 | 6.5 | 22 | 63 | 5.0 |

| SRD-D7.0 | 7.0 | 25 | 71 | 6.0 |

| SRD-D7.5 | 7.5 | 25 | 71 | 6.0 |

| SRD-D8.0 | 8.0 | 25 | 71 | 6.0 |

| SRD-D8.5 | 8.5 | 25 | 71 | 8.0 |

| SRD-D9.0 | 9.0 | 25 | 71 | 8.0 |

| SRD-D9.5 | 9.5 | 25 | 71 | 8.0 |

| SRD-D10.0 | 10.0 | 25 | 71 | 8.0 |

| SRD-D10.5 | 10.5 | 28 | 80 | 10.0 |

| SRD-D11.0 | 11.0 | 28 | 80 | 10.0 |

| SRD-D11.5 | 11.5 | 28 | 80 | 10.0 |

| SRD-D12.0 | 12.0 | 28 | 80 | 10.0 |