Carbide Drill Reamer

At Sundi Cutting Tools, our Carbide Drill Reamers are specialized composite tools designed to combine the functions of drilling and reaming into one tool. Made from solid carbide, these tools offer high-efficiency drilling combined with precise reaming capabilities. They are specifically engineered for medium to small hole diameters where single-step machining is required. The key advantages are reduced operations, improved efficiency, and consistent dimensional accuracy.

Typical Applications:

Automotive Manufacturing: Ideal for engine components, transmission housings, and other parts requiring precise hole dimensions and smooth surface finishes.

Aerospace: Perfect for drilling and reaming holes in critical aerospace components, where both precision and surface finish are essential.

General Manufacturing: Suitable for a wide range of industries, including mold making, precision machinery, and electronics, where high-quality holes with tight tolerances are required.

Need a high-efficiency tool for drilling and reaming?

Contact Sundi Cutting Tools today to learn more about our Carbide Drill Reamers and how they can optimize your machining processes.

- High wear resistance

- Reduce the machine time

- Stable Performance

- Easy to use

The Features of Carbide Drill Reamer

Integrated Drilling and Reaming

The Carbide Drill Reamer integrates both drilling and reaming into a single tool. The front section features a drilling edge for rough hole cutting and removing excess material, while the rear section features a reaming edge for finishing the hole to the required tolerance and surface finish.

Stable Dimensional Accuracy

The strong rigidity of solid carbide ensures minimal tool deformation during cutting, while the reaming edge and guide ribs work together to maintain hole roundness and cylindricity with high precision.

Reduced Operations and Improved Efficiency

This tool enables drilling → enlarging → reaming in a single clamping, eliminating the need to change tools. This reduces setup times, minimizes machine downtime, and increases overall machining efficiency.

Superior Surface Finish

The small cutting allowance of the reaming edge (usually 0.1–0.3mm) and the low-friction coating help achieve Ra 0.8–1.6 μm surface finish, eliminating the need for additional polishing operations.

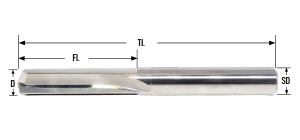

Specifications of Carbide Drill Reamer

Specification and Application

| Tech data | |

|---|---|

| Grade | SRC |

| Coating | DLC/AlTisiN/TiALCrN |

| Coating color | Colored/Bronze/BLACK |

| In Store | Yes |

| How to order | Contact Us |

| Download all Specification | Download |

| Order No. | D [mm] | FL [mm] | TL [mm] | SD h6 [mm] |

|---|---|---|---|---|

| SRC-D3.0 | 3.0 | 16 | 45 | 3.0 |

| SRC-D3.5 | 3.5 | 20 | 50 | 3.5 |

| SRC-D4.0 | 4.0 | 22 | 50 | 4.0 |

| SRC-D4.5 | 4.5 | 24 | 60 | 4.5 |

| SRC-D5.0 | 5.0 | 26 | 60 | 5.0 |

| SRC-D5.5 | 5.5 | 28 | 60 | 5.5 |

| SRC-D6.0 | 6.0 | 28 | 60 | 6.0 |

| SRC-D6.5 | 6.5 | 31 | 70 | 6.5 |

| SRC-D7.0 | 7.0 | 31 | 70 | 7.0 |

| SRC-D7.5 | 7.5 | 31 | 70 | 7.5 |

| Order No. | D [mm] | FL [mm] | TL [mm] | SD h6 [mm] |

|---|---|---|---|---|

| SRC-D8.0 | 8.0 | 37 | 80 | 8.0 |

| SRC-D8.5 | 8.5 | 37 | 80 | 8.5 |

| SRC-D9.0 | 9.0 | 40 | 80 | 9.0 |

| SRC-D9.5 | 9.5 | 40 | 80 | 9.5 |

| SRC-D10.0 | 10.0 | 43 | 90 | 10.0 |

| SRC-D11.0 | 11.0 | 47 | 100 | 11.0 |

| SRC-D12.0 | 12.0 | 51 | 100 | 12.0 |

| SRC-D13.0 | 13.0 | 51 | 100 | 13.0 |

| SRC-D14.0 | 14.0 | 54 | 105 | 14.0 |

| SRC-D15.0 | 15.0 | 56 | 110 | 15.0 |

| SRC-D16.0 | 16.0 | 58 | 115 | 16.0 |